The compressor is the heart of your fridge. Diagnosing compressor issues starts with listening to your refrigerator — when and where does the sound appear?

- If you hear no sounds and the compressor isn't running, or you hear a click, inspect the overload relay, start relay, and start capacitor.

- If you hear a constant, loud humming noise that doesn't shut off, your compressor may be broken or can't start.

The Basics

You may want to take a look at the component diagrams on our How a Refrigerator Works page, which will help you understand where all of the major components are so that you can more easily locate them.

It's also important to perform regular fridge maintenance. Keep it running well with these tips.

Before removing and replacing or continuity testing electrical components, power down the fridge. This will prevent damage to the components and prevent you from being electrocuted.

- If the fridge is pulled away from the wall, remove the plug.

- Otherwise, find the fridge’s circuit breaker in your breaker box and turn the circuit off.

- Check that the lights are off in in the fridge when you open the door

Reset Power

When refrigerators experience temporary power outages, they may enter a safe mode. The safe mode protects the fridge's internal components from electrical overloading. You'll have to reset the power to your fridge.

- Unplug your refrigerator. If the plug is too hard to reach, switch the circuit breaker off.

- Wait 5 minutes before returning power to the fridge.

- Once power is back, open your freezer and push the light switch 3 times to trigger a cooling cycle.

- Monitor temperature over the next 24 hours.

Dirty Condenser Coils

At the backside and bottom of your fridge are the condenser and its coils. The refrigerant passes through the coils which dissipates heat during the cooling cycle. As dust and debris pile onto the coils, the fridge becomes less efficient the fridge must work hard to cool down. If these coils are very dirty the compressor can overheat and shut down.

- Pull your fridge out and inspect coils.

- Your fridge may have an anti-tip bracket and can only be removed by pulling straight out from the wall.

- Clean dust off condenser coils and fan with a stiff condenser coil brush and vacuum.

- Work carefully during this task and avoid bending or damaging the tubes.

Failed Condenser Fan Motor

The condenser fan draws air over the compressor and through the condenser coils. If the fan motor isn't working normally, then the fridge won't cool properly, and the compressor can overheat with no air to cool it.

- Check the fan blade for physical obstructions. If the blades are cracked, splitting, or missing, replace the blades.

- Rotate the fan by hand. If it doesn't spin freely, replace the motor.

- If it spins freely, test the motor for continuity. Refrigerator Fans if the continuity test fails.

Faulty Defrost Timer

The defrost timer is in charge of initiating 30-minute heating cycles every 10 hours of fridge run time. If this unit fails, your fridge will be stuck in either the heating or cooling cycle. It's time to test the defrost timer. Your compressor won't run if the system is stuck in defrost, and it will likely also cause the bimetallic switch in the defrost system to open, or the thermal fuse (if present) will blow.

- In units with an adaptive defrost control board, you'll have to manually enable the defrost cycle.

- Turn the thermostat off for 15 seconds, then on for 5 seconds. Repeat this two more times, then turn the thermostat off.

- Defrost cycle should be turned on. Test the temperature with a thermometer to see if your fridge is heating up.

- With a manual timer, test between terminals 1 and 4 for continuity.

- Continuity here means that the cooling cycle is operating.

- Rotate the manual dial until hearing a click. Now test between pins 1 and 2 for continuity. This means that the heating cycle is working, and there should be no continuity between pins 1 and 4.

- Replace the timer with a new unit if continuity tests fail, or the fridge doesn't enter defrost mode.

Temperature Control Thermostat Failure

If the compressor won't run, the temperature control thermostat (also called a bi-metal thermostat) might be faulty. The thermostat allows power to flow through to the compressor, evaporator fan, and condenser fan.

- Continuity test the thermostat.

- Make sure it's cold from the fridge or sitting in ice water.

- Replace with a new one if its resistance value is outside of 0-1Ω.

Thermistor Failure

Another problem that could prevent your compressor from running is a faulty thermistor. The thermistor is a sensor that monitors the air temperature. It is connected to the control board. If the thermistor is defective, the refrigerator may not cool, or can cool continuously until the compressor overheats.

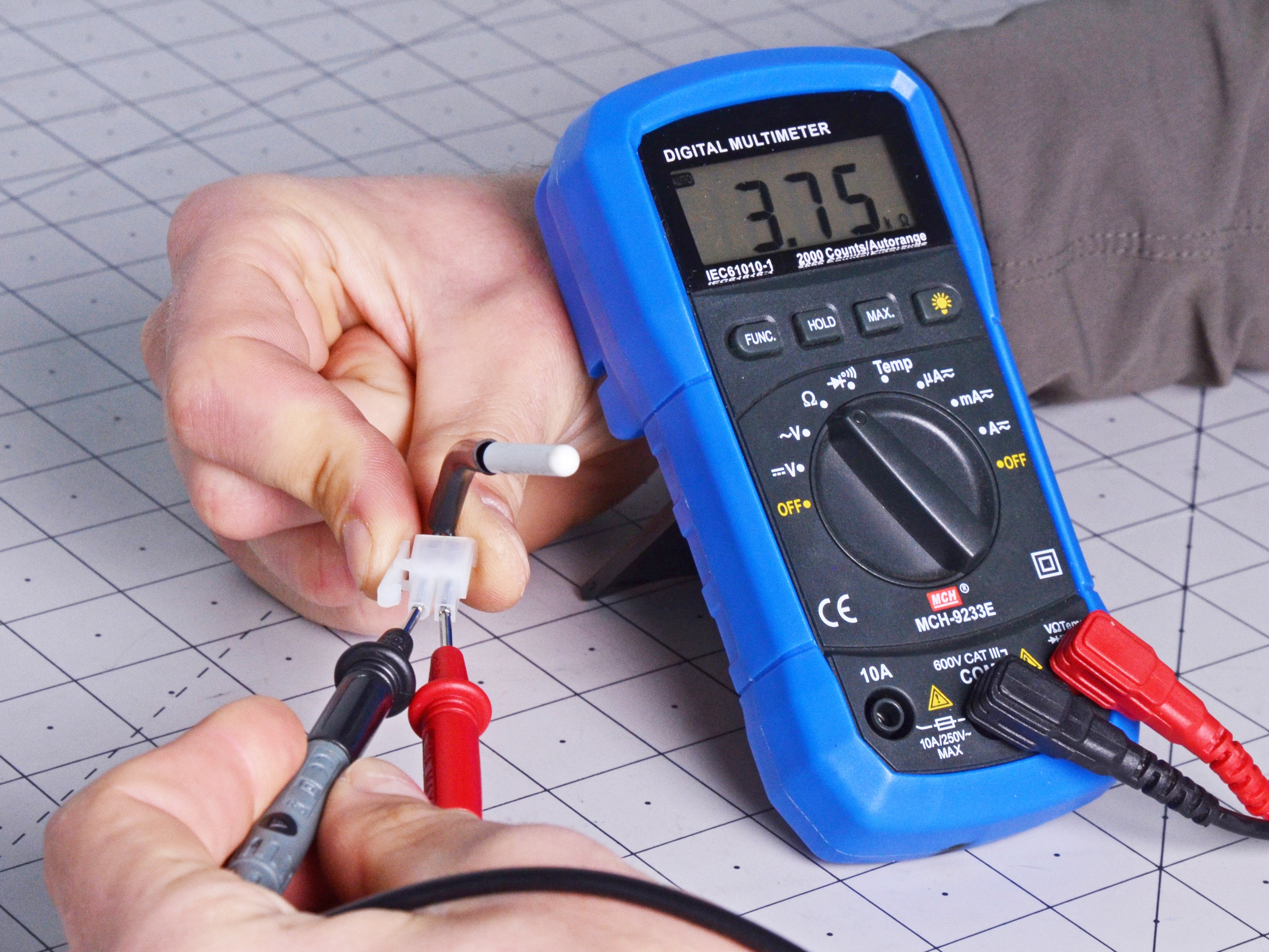

Grab a multimeter and continuity test the thermistor. Place the thermistor tip into a cup of ice water made from ice, water (just enough to cover the ice) and salt. You will need to find information on the resistance value expected for your refrigerator's various thermistors at 32°F (0°C).

If the thermistors test ok go on to the next item.

Temperature Control Board Failure

If the refrigerator is not cold enough, the temperature control board might be defective. The temperature control board provides the voltage to the fan motors and compressor. if the switches or relays on them fail, the compressor won't run.

- If the display LEDs or Temperature Setting button are not responding, it could signal that the board has failed.

- Remove the board from the fridge, and reconnect. Verify the wire connections are secure.

- Replace the temperature control board with a new unit.

Faulty Capacitor

If the capacitor has failed, the compressor will not be able to start and run as it should. Most newer refrigerators use a run capacitor, which stays in the circuit and improves the energy efficiency of the compressor. Some older refrigerators may have a start capacitor, which functions just at startup. These are not as common.

You may be able to tell what kind you have by looking at a couple of factors. Many run capacitors are polymer-type capacitors with a small rectangular block shape. There are cylindrical run capacitors, but they are less common (some LG fridges have them). The capacitance values of run capacitors tend to be smaller on refrigerators, something between 10 and 22µF (µF stands for microfarads, also abbreviated MFD).

A Typical Run Capacitor

Safely remove the capacitor and discharge with a discharge tool.

On smaller capacitors, you can use a screwdriver with an insulated handle to discharge it. But be careful as capacitors increase in size.

Test the capacitor with a capacitance meter; replace it if the value measured is outside the tolerance listed on the capacitor (usually +/- 5-10%).

A very quick functional check for a capacitor is to set your multimeter to the continuity function with the beeper on. Connect the capacitor to the leads for a few seconds. Then swap the leads to the opposite terminals. If the capacitor is at least storing some charge, you should get a short beep. This will not tell you if the capacitance is correct, only that the capacitor will store charge.

When you replace a capacitor, get the exact type of the existing capacitor, and the same capacitance value. You can safely use a capacitor with the same or higher voltage rating than the original.

If everything checks out, go to the next item.

Faulty Overload Relay

The overload relay is a protection device in the compressor circuit and is often combined with the start relay. You can find it plugged directly into the side of the compressor. If the fans are running and your compressor won’t start, or if you hear a clicking sound from the unit follow the troubleshooting below.

- Safely remove the start relay assembly.

- Check the overload relay for signs of overheating or arcing.

- This may be a hot module, burnt, or rattles when shaken.

- Check for continuity with a multimeter.

- Flip the unit over and test again. If there's no continuity, replace the unit.

Faulty Start Relay

The start relay is a small device mounted to the side of the compressor. It provides power to the run winding, along with the start winding, for a split second at startup to help get the compressor going. If the start relay is defective, the compressor may run intermittently or not at all, and the refrigerator will not get cold enough. The start relay should be replaced if defective.

- Safely remove the start relay assembly.

- Test Start Relay with a multimeter. View the video above and verify if your start relay is functioning.

- Replace the relay with a new one if it fails the testing or has a burnt odor. Depending on your start relay, you may have to test the start capacitor and overload relay first and use a process of elimination. If the other two components pass continuity tests, and your compressor isn't starting, try replacing your start relay.

Compressor Inverter Board Failure

Modern refrigerator compressor technology has shifted from single-phase DC motors to 3-phase DC-controlled AC motors.

What this means is that instead of the start relay assembly normally attached to the compressor pins — the start relay, overload relay, and overload capacitor — there is now a sealed motherboard and a lot of wires. The inverter board modulates the power supplied to the compressor and allows for more efficient operation.

This new technology is harder to test, so follow this helpful video.

The inverter board must be tested by the process of elimination.

- First, test the input voltages. The inverter board will have both a 120V AC main power supply voltage and a 4-6V DC voltage from the main control board. Remember to make all voltage measurements with everything connected.

- If one of these voltages is missing, the inverter board will not work.

- Backtrack to find the issue. You could have a faulty wire harness connector, a bad motherboard, or another issue.

- Second, follow the compressor continuity testing from above to verify your compressor isn't shorted and is okay.

- If the compressor is fine, and the board input voltages are fine, then your inverter board has failed and needs replacing.

Faulty Compressor

The compressor is your fridge's workhorse. By pressurizing the refrigerant, the compressor ultimately enables the evaporator to chill air.

If it isn't running at all:

Test the compressor for continuity. Resistance values vary based on the compressor, so view this video. Values outside of the range or a short to ground will mean replacing the compressor which is a costly repair. If your fridge is more than a few years old you're better off replacing the fridge instead of just the compressor.

- Test the compressor for continuity by following the video above.

- Resistance values vary based on the compressor.

- Values outside of the range or a short to ground will mean replacing the compressor, which is a costly repair.

- If your fridge is more than a few years old, you may be better off replacing the fridge instead of the compressor.

Main Control Board Failure

Finally, if the compressor won't run, the main control board might be defective. This is not common. Check the defrost system, cooling fans, and cooling controls first.

Related Pages

Refrigerator Compressor Running but Not Cooling

Fridge Not Cooling But Freezer Works

Refrigerator Won't Dispense Water

Freezer Not Freezing Ice Cream

Refrigerator Makes Humming Noise

Refrigerator Making Knocking Noise

3 件のコメント

Mi refrigerador Philips de 120 litros hace corto al enchufar. Que puede ser ?

Natalia - 返信 共有

Podría ser un condensador de arranque del compresor de refrigeración defectuoso.

Christian “Ope” Bürger - 返信 共有

Minha geladeira consul está sem gelar

Madalena de Albuquerque Silva - 返信 共有