Dremel 4000 Bearing Assembly Replacement

はじめに

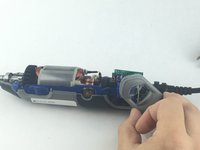

手順 1 に進むIf bearings are worn or if fan is damaged, the replacement of the entire bearing assembly is required. After opening the case, the bearing assembly can be lifted out by hand.

-

-

Start by removing the housing cap by unscrewing it.

-

Next, unscrew the now exposed collet nut while holding down the shaft lock button.

-

-

-

Using your hands, carefully remove hanger from casing.

Mine seems to have solid caps without the slot. How are this type removed?

This is getting worse. Maybe skipping the Collet Nut part threw me off - as there is no hanger. This description is PATHETIC!!!

I love how these pictures show you NOTHING related to what this guy is talking about

-

-

-

Remove the brush caps (one on each side) by using a flathead screwdriver bit.

I have found that the brushes are the most likely failure point on the Dremel tool. I haven’t purchased a new one in many years but they used to come with a spare set.

In general commutator brushes are made of a soft high carbon compound, usually found with new springs attached. The brushes can be carefully reshaped using files, sandpaper and a razor knife to fit the recesses of the tool.

Use the original to get necessary dimensions, a dial caliper is very helpful here to duplicate channels and recesses as well as determining how long the brushes should be. Should you need to shorten the brush a new concave can be established using a pencil or dowel wrapped in sandpaper being sure to match the concave to the channels so it matches the armature. It is preferable the curve be wider than the armature so edges don’t catch, it will naturally wear into a perfect curve. Blow off before installing.

Once the tool is reassembled turn on and off several times then run for a while varying the speed.

-

-

-

-

To clear access to the electrical assembly, remove the variable speed dial cap and blue power lever, and set them aside.

-

-

-

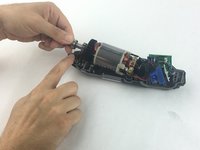

Each wire is fed through a small opening on the circuit board and held with a flat head screw.

-

Loosen the screw just enough to remove the wire by gently pulling it with your hand.

Hello I need to know or see where is plugged the blue wire, I think that know the problem it is disconnected? Thank you. if you need my e mail. charbonneau_eric66@hotmail.com

-

-

-

Carefully pull up on the shaft to lift out of the casing.

-

-

-

Firmly hold the field assembly in one hand and the bearing assembly in the other.

-

Carefully slide the bearing assemble out of the field assembly.

-

To reassemble your device, follow these instructions in reverse order.

To reassemble your device, follow these instructions in reverse order.

8 の人々がこのガイドを完成させました。

5 件のコメント

Nice guide. FYI, I've found that removing the rotor/bearing assembly is just as easy without removing the input power wires.

Absolutely, it is.

yeah why did we do that?

thats an abrupt end for someone trying to learn all of this the first time. which one of those is the field assembly and which is the bearing assembly? my guess is the bearing assembly is the cylinder looking thing on the right...

and then what? it just says do it all backwards to put it together again...? whyd we take it apart for? mines whistling or squealing or just going "EEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEE..." when i turn it on. just started today too. am i supposed to just, like, smack this can shaped part on the table and then cram it all back into its plastic case?

i mean, that works when the kids are acting up so im gonna give it a try.,..

Disassembly is shown, but main action of removing ball bearings from the shaft of the armature - vital essential sequence of removing - how to remove the collate pipe from the armature shaft, then how to pull out, ball bearings from the armature shaft is not shown. That is the most important procedure. No one wants to replace the whole armature and ball bearing assembly, at unnecessary high cost when the armature is okay. Please show how to remove ball bearings and replace them on the existing working armature.

Is this a joke??? Wanna maybe possibly tell US WHAT A COLLET NUT LOOKS LIKE?? I mean it's obviously very exposed (not exposed one bit. My Dremel 4000 looks exactly like it did before. No Collet nut suddenly stood out) and not all of us have advanced degrees in Dremel parts

Jeff Wagner - 返信

Dam Jeff. I am not sure if you are being sarcastic or not, but maybe you should go lie down for while.

itguyfla - 返信