はじめに

Use this guide to reflow the solder on the chips that usually cause the Xbox 360 to have a Red Ring of Death (RROD) failure. You'll need the high temperature output of a heat gun to accomplish the reflow.

Reflowing the motherboard of your Xbox 360 allows the solder balls located beneath the CPU, GPU, RAM, and other chips to reconnect with their contacts on the motherboard. To safeguard against future failure, we strongly recommend installing our Red Ring of Death Fix Kit after completing the reflow.

必要な工具と部品

-

-

Grasp the hard drive assembly and press the release button while lifting its front edge.

-

Remove the hard drive assembly from the top vent.

-

-

この手順で使用する道具:Xbox 360 Opening Tool$4.99

-

Insert the flat end of a spudger or the edge of an Xbox 360 opening tool into the small gap at the front edge of the bottom vent.

-

Pry the front edge of the bottom vent away from the faceplate.

You can avoid this step by pulling the front cover off. Just make sure you don't break the springs for the USB bay area.

Hello, thank you ifix for this guide, I followed this guide, I got stuck at some point but I resolved it. Also I want to share this resource: Step by Step guide to fix Xbox 360 errors it helped me go through all the things associated with Xbox 360 and the troubleshooting of errors. Hope this can also help you all.

-

-

-

Insert the flat edge of a spudger between the faceplate and the outer casing near the power button.

-

Run your spudger along the edge of the faceplate to release the clips securing it to the front of the console.

The faceplate just pulls off, using a tool is completely unneccessary. https://beta.support.xbox.com/help/xbox-...

-

-

-

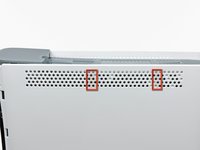

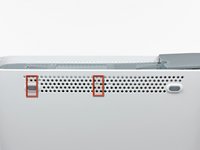

The top vent is secured to the console via clips. The first two clips are located underneath the top vent closest to the faceplate, as shown in the pictures.

-

-

-

Insert the flat end of a spudger into the small gaps previously mentioned to release the clips.

I found this step difficult. I wasn't able to see where the clips were from the pictures. If you look at step 14 you can see what the clips look like after the vent is taken off. Once you realize where they are it is a lot easier.

-

-

-

Stand the console vertically with the top edge facing down.

-

Carefully peel the warranty sticker off the console.

LOL “Romove the warenty seal”

-

-

-

-

Press the Xbox 360 opening tool down into the clips securing the lower case to the upper case near the I/O ports.

-

While pressing down on the tool, push the lower and upper cases apart to separate the retaining clips.

I didn't have an XBox tool, so I followed instructions in this video for this step (https://www.youtube.com/watch?v=qaxIB6cX...) to pry it open with your fingers and a screwdriver.

The small (metal) women's hair clip is best for un-latching the tabs. The screw drivers just make the holes bigger.

Denny Ross - 返信

You can also use the pointed end of a plastic spudger to push each clip free while you separate the case with your free hand.

-

-

-

While pushing the upper and lower cases apart, use the tip of a spudger or the finger of an Xbox 360 opening tool to push the long clip highlighted in red toward the center of the 360.

-

The clip should release, leaving the clips near the power connector as the only thing holding the upper and lower cases together.

-

-

-

Use the tip of a spudger to release the clip securing the eject button to the metal casing.

-

Insert the flat end of a spudger between the eject button and the optical drive.

-

Pry the eject button off its retaining posts and remove it from the 360.

-

-

-

Remove the six silver 64 mm T10 Torx screws securing the upper case to the metal casing.

-

-

-

Peel the silver tape securing the optical drive to the metal casing.

Looking at mine, I doubt it. It looks like standard foil tape

-

-

-

Grab the power connector by its cables and pull it straight out of its socket on the optical drive.

-

Disconnect the SATA data connector from its socket on the optical drive by pulling it straight away.

I found the power cable to be very tough to get out, at least it is the first time doing this.

I found it much easier to remove the SATA cable after lifting the assembly mostly out of the case.

-

-

-

Lift the optical drive assembly out of the metal casing.

Be careful not to lose or break the two teeny metal clips securing the optical drive assembly snugly to the metal casing on either side of the drive's front face. I used a spudger to press in the topmost tines on these clips because they were catching on the drive and bending up. The clips should stay on the metal housing, not come off with the drive.

-

-

-

Insert the flat end of a spudger into the small rectangular opening on the top of the cooling fan duct.

-

Carefully release the fan duct retaining clip and remove the fan duct from the Xbox.

-

The clip can alternatively be released using the metal finger of an Xbox 360 opening tool.

Fair warning for people using this guide for maintenance, the inside will likely have a coating of fine dust or dirt

-

-

-

While lifting the metal chassis strip above the dual fans, pull the fans toward the center of the motherboard.

Cleaning out the fan now, will help problems in the future.

Joe Begley - 返信

Do Step 35 first (remove the fan connector from the motherboard), otherwise as you pull the fans forward out of the metal bracket you risk stressing the connector's attachment to the motherboard (because the fans will press against the connector as you pull them forward).

There are small black feet on the bottom of the fan assembly, You can push up from the bottom of the case if needed.

these are powerful fans. im having over heating issues with a brushless motor. anything less than a 120mm pc fan does nothing. but i must keep the top off to fit the 120 and adequate heat removal. so i wanna use tbis turbo fan and mount i ti the lid.

how do i remove the blades and get to the bearings and guts??

theres no rear access hole hiding under the specs sticker.

please help! thank

-

-

-

Use the flat end of a spudger to release the clips securing the RF module shield along the top and the left edge of the RF module.

-

Remove the RF module shield from the console.

-

-

-

Remove three 5.6 mm T8 Torx screws securing the RF module to the metal chassis.

for whatever reason the T8 screws holding the RF receiver on my unit were torqued on pretty hard. almost impossible to get off. IS taking the RF off really necessary?

They all seem like that the further down we go. Unless you're here to just repaste the board, you have to take it off

-

-

-

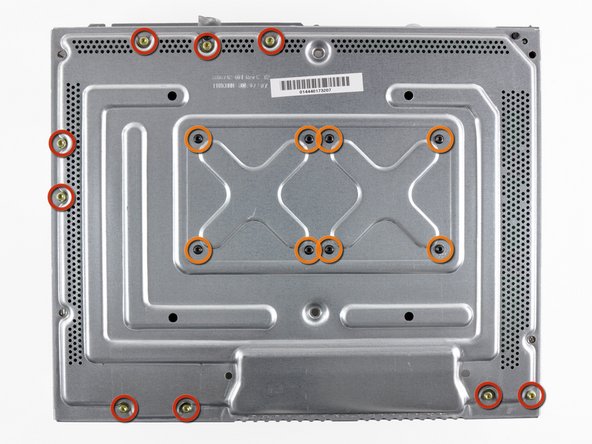

Remove the following screws securing the motherboard to the metal casing:

-

Nine gold 11 mm T10 Torx screws.

-

Eight black 5.6 mm T8 Torx screws.

kinda hard for a KID to do this huh also I am a 9 year old you get it

Andy Ewing - 返信

well, it almost as if this is labeled as Difficult in the beginning!

The T8’s were T9’s on mine. This guide could be wrong, or my toolkit was mislabeled. If you can’t get the T8’s out, try a T9 before stripping the screws!

They were T8’s for me

Ryan Lee -

-

-

-

Insert the tip of a small flathead screwdriver between the X clamp and its retaining post on the heat sink.

-

Pry the X clamp away from its retaining post until it is lifted above the small groove cut into the retaining post.

The instructions on how to remove the x clamps are insufficient. I had a great deal of trouble with them. The small flathead screwdriver included with the kit is too small and weak to do the job. I ended up Googling other how-to's. I used a larger screwdriver and FINALLY popped them off, however as careful as I tried to be in the process I accidentally damaged a few traces around the screw hole. Repair was a failure, still have 3 red lights. Waste of time and money.

Why the heck would you suggest using a screwdriver to release the x-clamps from the motherboard, knowing that the screwdriver could slip and damage some of the traces on the motherboard!? Didn't see the comment about placing a piece of cardboard on the motherboard to prevent scratching until I had already screwed up my Xbox. How hard would it be for iFixit to develop a tool to easily remove the x-clamps like they did to open the Xbox? I wanted to do this to prevent any possibility of overheating, and went from a working Xbox to a dead one because of this bad step. Definitely took my view of iFixit down a notch, will be much more hesitant to recommend their tools and guides after this. Would like a refund but I know that's not going to happen. Super ticked!

Same thing just happened to me, the tiny screw driver they say to use has next to 0 leverage to get it off. Now my repair kit is useless cause I physically removed some of the bits because my screwdriver slipped.

Forren -

I found that inserting a sprudger between the X clamp and retaining post and turning while lifting worked well without damaging the board

The tool provided in the kit is completely incapable of performing this step (prying the X off the post).

I originally had a lot of issues prying them up; I was really worried about accidentally scratching the board. The instructions don’t seem fully adequate. Instead, first pry all four corners as high up as possible, pointing the screwdriver towards the center of the X clamp. If you pry them practically horizontally, then it makes the whole process a lot easier. Then work individually, pushing each corner slowly outwards and upwards, putting the screwdriver in from above (not the side as step 42 shows, too dangerous) into the small space between the screw and the X. Be careful at this point, just in case. Also, DON’T use the small flat head screwdriver provided; it’s too tiny to get proper leverage. I used 1/8 in. See this tutorial: https://www.youtube.com/watch?v=pHzEV3c_...

Maybe the tiny flathead in the kit I got is newer than the old ones…

DO NOT stick the screwdriver vertical as shown in step 41!

Instead use it like step 42. Insert it only that way, between each front of the X clip arm and the post, and turn it so the screwdriver turn pushes the bottom of the X clip off the post.

No risk of damaging the board this way.

Instructions were very unclear, but comments helped. Both used cardboard and the tutorial found here https://www.youtube.com/watch?v=pHzEV3c_... as mentioned by Sophia Vera. Took my time, and mostly used a longer screwdriver like in step 42. Once the first 3 clips come off, the fourth one essentially falls off, so be ready to catch your heat block when you pop the third one.

-

-

Is the x-clamp supposed to be reinstalled? It's not pictured in any part of the instructions after this point, so I did not reinstall it, and putting the xbox back together now is different than taking it apart.

The X-clamps are not reused. Since you install machine screws in place of the X-clamp mounting posts, you do not reinstall the eight screws highlighted in orange on step 41.

-

-

Insert the tip of a small flathead screwdriver between the X clamp and its retaining post on the heat sink.

-

Pry the X clamp away from its retaining post until it is lifted above the small groove cut into the retaining post.

-

Remove the CPU heat sink from the motherboard. When reinstalling the CPU heat sink, be sure to apply a new layer of thermal paste.

-

-

-

If replacing the motherboard transfer the four thermal pads on the underside of the motherboard to your new motherboard.

-

Motherboard remains.

I'm keeping the same motherboard so do I have to replace or need the thermal pads? For this guide

Replace them if they're crusty, or you can replace them

-

-

-

Lay the motherboard with the processor side facing down on the flat metal bottom of the the bare chassis (with its open side facing down) as seen in the second picture. Allow the tall USB socket to hang over the edge of the chassis so the board sits flat.

-

Use a heat gun on the LOW setting to heat the entire back of the motherboard for one minute. Be sure to continually sweep the heat gun back and forth across the face of the motherboard to evenly heat it.

Rather than using a heat gun, I have had good results using a domestic oven. Pre-heat the oven to 230C then place the motherboard in the oven component side up. I use a piece of cardboard to support the board in the oven. Heat for a couple of minutes only, you should be able to smell the flux at this time. Turn the oven off and leave for a couple of minutes, then gently crack the oven door open slightly and leave like this until cool. This sort of simulates the ramp up/hold/ramp down of the normal soldering process. I have reflowed a couple of Xbox 360 motherboards like this with good results.

Brett Lymn - 返信

Wouldn't this heat up the board uniformly? Including the capacitors? I'm thinking that is a recipe for exploding electrical components.

Joshua -

do not do this!!! only an idiot would put the whole board in the oven. i did it and the capacitors popped and micro capacitors fell off the bottom. yes i'm an idiot

Anyone performing these heating steps should really shroud the areas that don't need then heat. If you are not an expert with the heat gun it is easy to damage other parts. I recommend using silicone oven pads to lay over everything but CPU and GPU areas. There is also a danger of over heating RAM chips. The key here is an even increase in temp for a UNIFORM temp of chips. I have done about 500 of these and when I first started they would pop errors again after a few heat-ups and cool downs. I even broke a few heating too fast and too quick. Heres the deal, cover other areas, start with heat gun on low 16 inches away moving in circles move closer. Increase heat over course of 4-5 min.

-

-

-

With your heat gun set to HIGH, evenly heat the area boxed in red for four minutes.

-

After heating the area boxed in red for four minutes, turn off your heat gun and allow the motherboard to cool down to room temperature without moving or disturbing it in any way.

I have a heat gun with lo (300 C) and hi (600 C) settings. I've fixed 2 PS3 YLOD (excellent IFIXIT guide for that, by the way) and have just tried to fix an XBOX using this guide. Within 2 minutes of starting , using the hi setting and keeping the gun moving , one of the dark areas around the small chips started to bubble. I haven't tested the result, yet, but suspect the worst....

I think the guide should be more informative and precise about the heat requirement.

Next time I'm going to follow the settings (lo) and timings the PS3 guide suggests.

Yeah i would not be using a heat gun on high especially for4 minutes try a good hair dryer on high should be hot enough to reflow but not so hot it will damage componets

A standard hair dryer only gets to about 200°C, which isnt high enough to melt the components on the board.

bvop -

I have heat gun, that is able to set temperature (from 50 to 600 celsius) so what is the best value for LOW and HIGH? I had seen a lot of videos on YT and read a lot of manuals, but never had found out, the correct temperature…

Well I use 420 Celsius to remove and replace electrical components on a MB for both computers and Game consoles. So why not use that temp for high and say 250-300 for low? At 420, holding it in one place over the component, it only takes about less than 1 minute to get the solder to re-flow to work it.

Brian Wall - 返信

Here's one... i just changed out all the blown capacitors and did the entire reflow process. Plugged in the system partially assembled, just for testing purposes. Worked, no red ring. Turned it off and reassembled the entire system, plugged it in, then it red ringed... no power, no fans, nothing.

Disassembled out of shell, it turned on with no red ring. Put in a game and it worked with no issues. Assembled the top cover with only one screw in to test, it red ringed again....

What does this mean?? Makes no sense to me.

Hi Josh, I did the same a week ago. Removed and re-soldered 7 blown capacitors and did the reflow with a heat gun. I also added flux around the cpu and gpu. And finally added new thermal paste. The console started up and no RROD. It lasted a week and last night the RROD is back. My heat gun only has 3 settings. I used the low setting for warming up the board and the medium for 4 minutes on the chips. The medium setting is around 400 c. My theory is there was somewhat of a reflow of the solder and made a connection but it broke again. I've opened the console again and will try the reflow again but at the high setting to see if and how long this reflow lasts. Take care!

Tom -

-

21 件のコメント

Is there a similar guide for XBOX 360s?

Yes, there is - and It worked for me!

Dave -

What temperature ranges should I be aiming for? I have a variable temp head gun and no idea of what temperatures are best for both stages.

The heat gun they are using has a 570 F low-setting. While that doesn't give you an EXACT temperature, it should give you some idea of what they're using.

what happend

Code 0013 I followed guide and it already has the rod fix kit and still two left red lights flash

Andy Brown - 返信

the two red rings mean it overheated and need to cool down you just had to cool it down not do all of this!

Aurelio -

Is there a tutorial for more professional tools?

Exact temperatures and times for the chip surface and the down side of the board (with K-Type thermo couppler under kapton tape) with a IR-Rework-Station, perhaps also for hot air.

With a liquid flux, a dual digital thermometer etc..

That is not "High-End" stuff, this is possible for normal people.

I think, a liquid flux is the minimum for better results.

I have this stuff, but not a "recipe".

Hi thanks for wrecking trade for repairers, however this type of fix is temporary & should be done properly by someone trained with the right equipment.

I just did this to keep my xbox going until gta 5 came out on PC no point in getting it fixed right lol.

Lmao Brian, “Big Repair” shill, the fact there is ANY controversy at all about having DIY repairs exist is astonishing!

Silly tutorial..

Why do these chips have heat sinks??? To remove heat to prolong chip life.

And you want to apply heat from a hot air gun heating chips past their rated thermal limit to the point where solder re-flows (approx. 400 degrees C) Most chips have an upward thermal limit of around 120 degrees C.

Take it to a professional do not do this yourself. Remember that the chips have internal solder connections as well so whilst your heating up the chips to reflow the solder you also run the risk of detaching the internal connections thus forever ruining the chip.

Dude, lead free solder doesn't melt until 220 *C... How are you supposed to reflow at 120... Heat from soldering does nothing to chip life, as long as you are within the manufacturers soldering heat limits. The Chip wears out from internal electrically generated heat, which is completely different. How do you think they solder GPUs to graphics cards that have a thermal limit of about 100*C.... Also 400 *C wtf... Have you ever soldered in your life? 60-40 solder melts at 188 *C

FYI I've done this 5 times to my xbox since 2008. it still works everytime after. I don't even use it anymore so theres no point in getting it reflowed with lead solder.

I did this Tutorial W/O doing the Heat Gun part and mine works great.

Laurap6286 - 返信

You should not do this. This is NOT how you reflow a board properly. You are just warping your board and causing damage. Sad that a reputable company like iFixit has this garbage on their site.

About how long does this last?

I just have to say this is not a permanent fix and will probably happen again shortly after using the console. The only way to permanetly fix the RROD caused by cold solder joints is by reballing the GPU.

leothepool - 返信

WARNING: Just replacing the drive will not make it work correctly. Microsoft has married the drives to the motherboard. Hence, in order to get full operation out of the drive you'll have to perform more steps not listed here. Search in the FAQ on this specific topic for more details. Otherwise, before buying a new drive, try cleaning the inside of the old one and/or replace the belt involved in opening and closing the drive door.

- Good Luck

Eric - 返信

Thanks..helped!

joseph zulu - 返信

bress the button and lift with the same hand! i thought mine was stuck because of this pic!!!

Maths with Luigi - 返信