はじめに

放熱グリスの塗布はプロセッサを冷却するために欠かせません。修理作業でヒートシンクあるいはCPUを取り出した後、この手順を参照してサーマルペーストを塗布してください。CPUに特化したより高度な方法についてはArctic Silverのページをご覧ください。

携帯電話に放熱グリスを塗布する方法については、こちらのガイドを参照してください。

必要な工具と部品

-

-

-

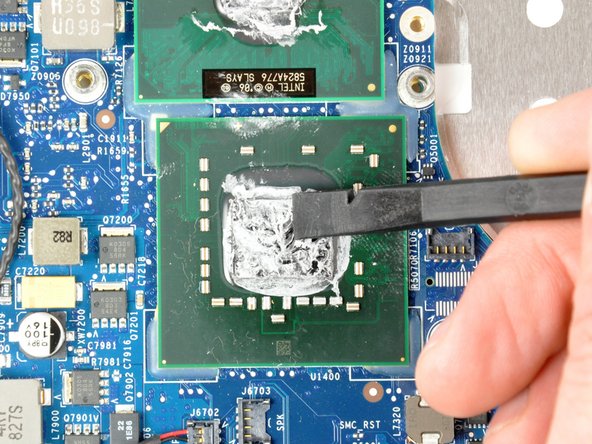

コーヒーフィルターか糸くずの出ないリントフリーの布に少量のイソプロピロアルコール(別名IPA、濃度90%以上)を使って、ヒートシンク上のサーマルコンタクト表面に塗付してください。

-

IPAの代わりに、クリーニング専用の溶剤ArctiCleanサーマル素材リムーバーなどを使うこともできます。

-

表面上が綺麗になったら、 新しいコーヒーフィルターかリントフリーの布にIPAを少量滴らして、表面上の油脂などを完全に拭き取ります。

-

チップやヒートシンクを触らないでください。埃やゴミが付着するのを防ぎます。指紋でもチップ上に熱を伝導する障害となることがあります。

-

ヒートシンクを完全に乾かします!

-

-

-

新しく放熱グリスを塗布するには、特定のプロセッサータイプ別に推奨される塗布方法に従ってくださいー垂直方向か、水平方向に塗布か、中央に点を描くように塗るのか、表面に塗るのかという違いです。表面上に広がると、気泡を閉じ込める可能性があることに注意してください。

-

放熱グリスを塗布する場合、以下の方法で行ってください。

-

サンドイッチ用のビニールバッグやサランラップなどを人差し指の先端を巻きます。

-

ほんの僅かな量の放熱グリスをプロセッサーコアの上に塗布します。

-

プロセッサーコア全体に付けられた放熱グリスを丁寧に指で伸ばします。

-

これでプロセッサーは新しいヒートシンク再装着の準備ができました。

-

デバイスを再組み立てする際は、これらを逆の順番に従って作業を進めてください。

1128 の人々がこのガイドを完成させました。

以下の翻訳者の皆さんにお礼を申し上げます:

100%

これらの翻訳者の方々は世界を修理する私たちのサポートをしてくれています。 あなたも貢献してみませんか?

翻訳を始める ›

40件のガイドコメント

For heat sinks with a spring on the screws: Wonder why there are springs on the heat sink screws? Do not over tighten them, the springs are there to help you apply the correct amount of pressure on to the CPU and GPU. If you tighten them all the way, it may not be the correct pressure! Leave maybe 1 mm of space, just before the screw stops turning. iFixit forgot to mention this important part, and also in the heat paste guide!!

This is completely untrue. The holes bored in the heat sinks are in fact a larger diameter than both the threads and the shoulder of the heat sink screws. The screws should be fully tightened (as they were from the factory) to maintain correct pressure against the processors.

I have two green lights on my xbox slim ... Should I do all of this to get rid of them? I'm not sure if they are supposed to be green. I bought my wii and remotes from a refurbishing place. I don't have the red ring of death, but I think it is from over heating.

OMG Hi -

Thank you so much for this! Have been struggling for months with CPU diode sensor reporting 262F/128C and CPU dropping to 0.8 Ghz due to Speedstep. Loosened the screws a little and the sensor is back to normal. I cannot thank you enough for this!