A1398 MacBook Pro 15" Mid 2015 Missing pad on L4010

Hello,

I've recently figured out that for some reason my facetime camera is not working even after SMC or PRAM reset procedures.

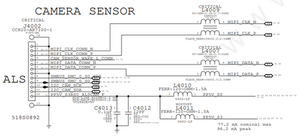

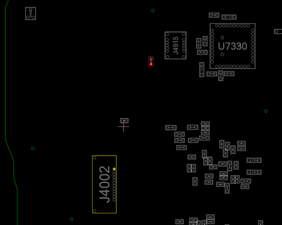

I was able to locate the problem and it was an L4010 chip near the backlight connector of the keyboard.

Due to my mistake, while I was working on the keyboard, I've accidentally connected the facetime camera connector while the battery is connected. I think this caused the problem.

To fix the issue, I was able to order the chip for L4010 which is FERR-120-ohm-1.5A from Digikey.

The problem is that due to the burnt L4010 chip, the PCB pad is missing, and need to find another place to solder the chip by jumping wire.

Is there any good place to put jumper wire for the chip?

I've included some ref photos for the boards.

この質問は役に立ちましたか?

2

2

893

893  2.3千

2.3千