Photosmart 7510e - Paper not feeding automatically, Will feed Manually

With paper in the printer "No Paper Error" keeps coming up. When the printer status page it printed the feed rollers move down to the paper however they do not roll or move at all to pull the paper through the printer. All of the additional rollers after the feed rollers are working properly because when you push just one sheet of paper through the feed rollers the second rollers will grab the paper and pull through the duplexer rollers.

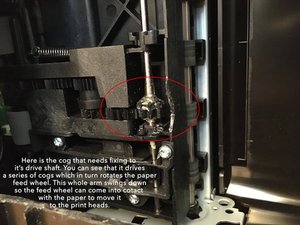

I am looking for a guide to the teardown process to get to the feed rollers to see if a gear is broken.

Thank you for any help.

2

2  2

2