はじめに

In this repair guide you will learn to disassemble your Dell LED / Laser printer to get to the main mechanics to clean them and put them back together, to solve error 007-371.

必要な工具と部品

-

-

Does your Dell C1760nw ( and some other LED/laserprinter models) show you incessantly the error 007-371? Then this repair guide is made for you!

-

-

-

Remove the front paper tray by slightly bending it carefully and angling it to release the peg from the hinge slot.

-

-

-

Remove the bar at the top and the front. (It snaps out with a little effort.)

-

-

-

Remove two srews from the front. And to take off the cover leverage remove the tabs diagonally from the front over the latching.

-

-

-

Carefully lift the cover (Attention: cable connection to the display is hanging there) and rack it to the back of the printer (move it back and forth to unhook the locking nipple): unplug the display connector (yellow lines) from the I/O board, unroute the cable and remove the cover.

-

-

-

Place the printer on the right side and remove the left side panel (there are 2 lugs under the printer)

-

-

-

Reposition the printer and hold the disengaged lugs in the disengaged position. Open the rear flap and slide the side panel backwards while moving away from the printer.

-

-

-

-

The WLAN card is secured with a screw-> remove it, carefully unplug the WLAN card and remove the WLAN bracket together with the cable

-

-

-

Loosen all connectors (pull plugs carefully out of sockets)

-

Pull both flexible cables out of sockets. Caution: the wider flexible cable has a base with lock. Lift it carefully with a fingernail, this releases the flexible cable and allows it to be easily pulled out of the socket.

-

I/O card is secured with 4 screws, loosen all 4.

-

There is another screw on the USB port: Loosen it

-

-

-

The metal plate under the I/O card (which holds the I/O card) is secured with 3 screws. Remove all 3 screws

-

-

-

The fan is secured to this plate with a screw (red arrow): Loosen the screw and unlock the locking device on the other side of the fan.

-

Remove the fan, disconnect the cables and plugs on the upper control board (no photo).

-

-

-

Unroute all cable harnesses on the left side from the guides.

-

Remove the cable guide bracket and hang it from the remaining cable harnesses on the printer.

-

-

-

A) Remove plastic bracket with gear for paper feed (2 screws) - No photo!

-

B) Remove main drive

-

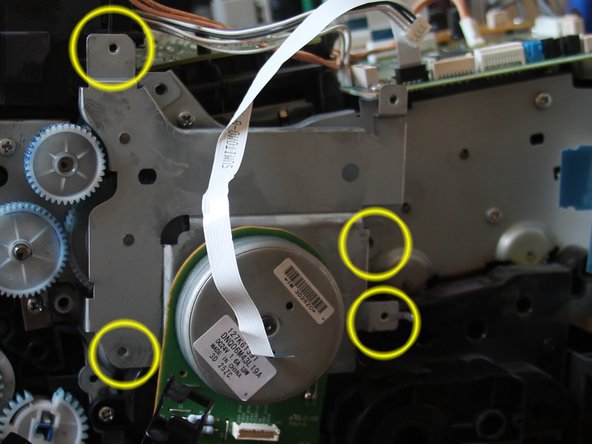

C) Remove board with color control (4 screws)

-

-

-

Loosen 4 screws

-

Pull the main gearbox carefully and straight off the printer. (Caution: loose gears!)

-

Last photo: This is what the dismantled main gearbox looks like: The completely muddy (color & grease) drive gear is the black (below)

-

-

-

Carefully pull the upper flexible cable out of the base

-

on the right side: 4 flexible cables with base lock. With fingernail: Open the lock, then carefully lift the flexible cable by the blue tab and remove it from the base. (hand)

-

-

-

Next, we remove the color control gear (black, large plastic bracket with 15 meshing gears (5 screws have to be loosened).

-

-

-

Now the chassis should be cleaned (only for the good feeling! and because of the care...)

-

-

-

The assembly is done in reverse order... Until the printer only needs the right and front housing part plus the paper flap.

-

If the error message 007-371 appears again at the first attempt of the printout, this is nothing unusual. The paint mixing drive usually still needs a "boost".

-

Turn the printer off and on again a short time later. Now you help the gear a little bit on the jumps: for this you put on a screwdriver as shown in picture 1, hold it with a little pressure so that you can get the gear wheel touched with it a little in motion when it is released by the small relay.

-

This usually does not happen by itself during the first printing process (although the spring in the gearbox, which you probably noticed earlier, should actually trigger this momentum). So, put on the screwdriver like this and send a print job.

-

In picture 2 you can see a better close-up to attach the screwdriver exactly.

-

If everything works, then reassemble everything else and: DONE!

-

Congratulations, you did it!

Congratulations, you did it!

5 の人々がこのガイドを完成させました。

以下の翻訳者の皆さんにお礼を申し上げます:

100%

これらの翻訳者の方々は世界を修理する私たちのサポートをしてくれています。 あなたも貢献してみませんか?

翻訳を始める ›

添付文書

3 件のコメント

it looks so easy LOL but then when you know what your doing it helps!

Thanks all the same.

BC

Ben Cowell - 返信